I.Introduction

Vanillin is one of the most popular and widely used flavor compounds in the world. Traditionally, it has been extracted from vanilla beans, which are expensive and face challenges regarding sustainability and supply chain vulnerabilities. However, with the advancements in biotechnology, particularly in the field of microbial biotransformation, a new era for natural vanillin production has emerged. Utilizing microorganisms for the biological transformation of natural raw materials has provided an economically viable pathway for the synthesis of vanillin. This approach not only addresses sustainability concerns but also offers innovative solutions for the flavor industry. Research conducted by the SRM Institute of Science and Technology (SRMIST) has provided a comprehensive review of eclectic approaches to the biological synthesis of vanillin and their applications in the food sector, summarizing various techniques for the biological synthesis of vanillin from different substrates and its diverse applications in the food industry.

II. How to Get Natural Vanillin From Renewable Resources

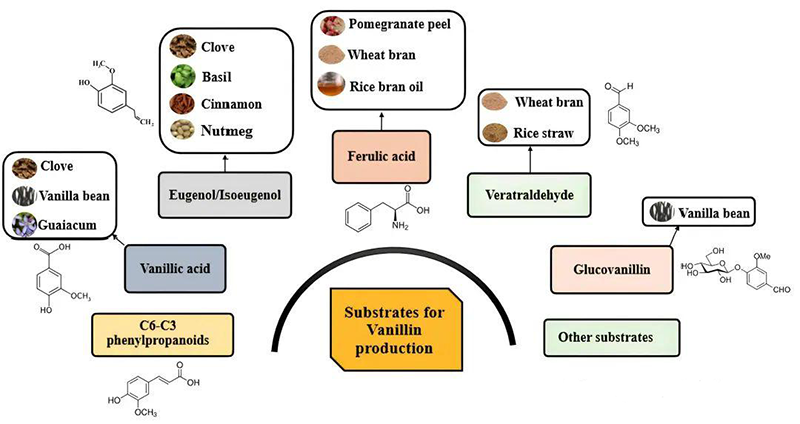

Utilization of Ferulic Acid as a Substrate

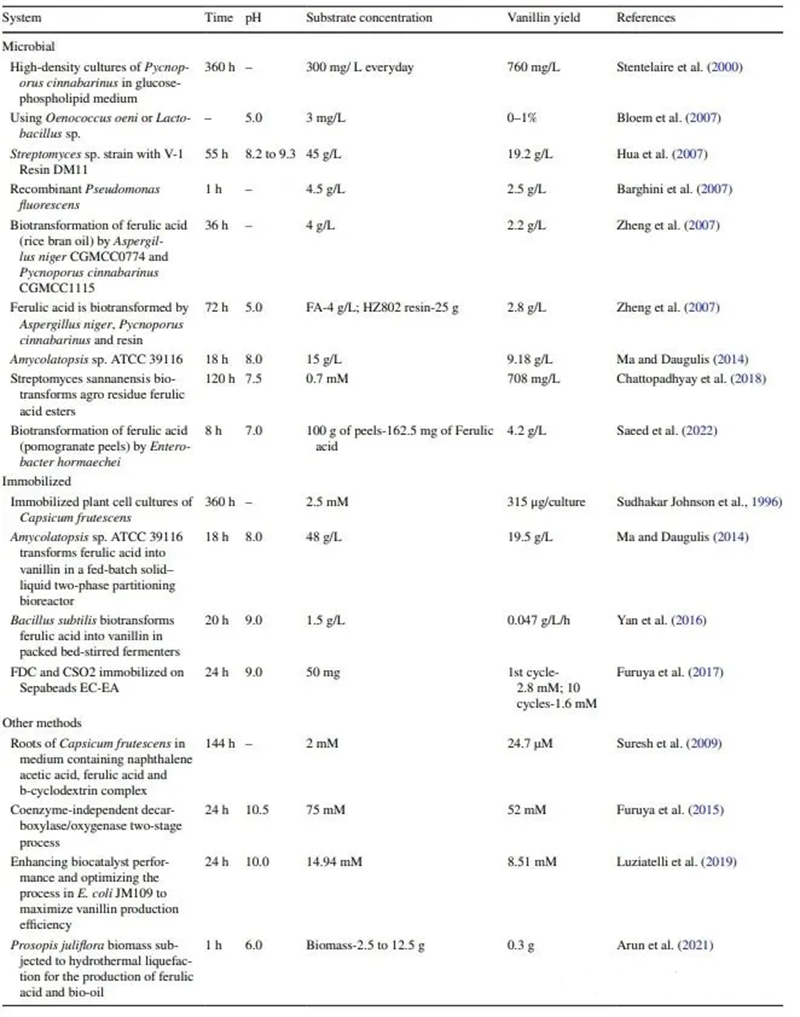

Ferulic acid, derived from sources like rice bran and oat bran, exhibits structural similarities to vanillin and serves as a widely used precursor substrate for vanillin production. Various microorganisms such as Pseudomonas, Aspergillus, Streptomyces, and fungi have been employed for the production of vanillin from ferulic acid. Notably, species like Amycolatopsis and White-rot fungi have been identified as potential candidates for producing vanillin from ferulic acid. Several studies have investigated the production of vanillin from ferulic acid using microorganisms, enzymatic methods, and immobilized systems, highlighting the versatility and potential of this approach.

Enzymatic synthesis of vanillin from ferulic acid involves the key enzyme feruloyl esterase, which catalyzes the hydrolysis of the ester bond in ferulic acid, releasing vanillin and other related by-products. By exploring the optimal quantity of vanillin biosynthetic enzymes in cell-free systems, researchers have developed an improved recombinant Escherichia coli strain capable of converting ferulic acid (20mM) into vanillin (15mM). Additionally, the utilization of microbial cell immobilization has garnered attention due to its excellent biocompatibility and stability under various conditions. A novel immobilization technique for vanillin production from ferulic acid has been developed, eliminating the need for coenzymes. This approach involves coenzyme-independent decarboxylase and coenzyme-independent oxygenase responsible for the conversion of ferulic acid into vanillin. The co-immobilization of FDC and CSO2 enables the production of 2.5 mg of vanillin from ferulic acid in ten reaction cycles, marking a pioneering instance of vanillin production through immobilized enzyme biotechnology.

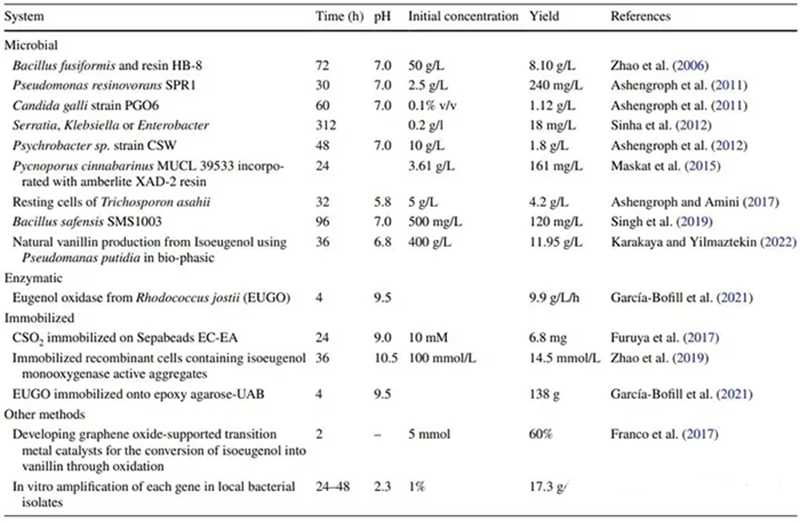

Utilization of Eugenol/Isoeugenol as a Substrate

Eugenol and isoeugenol, when subjected to bioconversion, produce vanillin and its related metabolites, which have been found to possess various applications and significant economic value. Several studies have explored the use of genetically modified and naturally occurring microorganisms to synthesize vanillin from eugenol. The potential for eugenol degradation has been observed in various bacteria and fungi, including but not limited to Bacillus, Pseudomonas, Aspergillus, and Rhodococcus, demonstrating their capability in eugenol-derived vanillin production. The utilization of eugenol oxidase (EUGO) as an enzyme for vanillin production in an industrial environment has shown significant potential. EUGO exhibits stability and activity over a broad pH range, with soluble EUGO increasing activity and reducing reaction time. Moreover, the use of immobilized EUGO allows for the recovery of the biocatalyst in up to 18 reaction cycles, leading to a more than 12-fold increase in biocatalyst yield. Similarly, immobilized enzyme CSO2 can promote the conversion of isoeugenol into vanillin without relying on coenzymes.

Other Substrates

In addition to ferulic acid and eugenol, other compounds such as vanillic acid and C6-C3 phenylpropanoids have been identified as potential substrates for vanillin production. Vanillic acid, produced as a by-product of lignin degradation or as a component competing in metabolic pathways, is considered a key precursor for bio-based vanillin production. Furthermore, providing insights into the utilization of C6-C3 phenylpropanoids for vanillin synthesis presents a unique opportunity for sustainable and innovative flavor innovation.

In conclusion, the utilization of renewable resources for natural vanillin production through microbial biotransformation is a landmark development in the flavor industry. This approach offers an alternative, sustainable pathway for the production of vanillin, addressing sustainability concerns and reducing reliance on traditional extraction methods. The diverse applications and economic value of vanillin across the food industry underscore the importance of continued research and development in this area. Future advancements in the field of natural vanillin production have the potential to revolutionize the flavor industry, providing sustainable and eco-friendly alternatives for flavor innovation. As we continue to harness the potential of renewable resources and biotechnological advancements, the production of natural vanillin from diverse substrates presents a promising avenue for sustainable flavor innovation.

III. What are the benefits of using renewable resources to produce natural vanillin

Environmentally Friendly: Using renewable resources such as plants and biomass waste to produce vanillin can reduce the need for fossil fuels, reduce negative impacts on the environment, and reduce greenhouse gas emissions.

Sustainability: Utilizing renewable resources enables a sustainable supply of energy and raw materials, helping to protect natural resources and meet the needs of future generations.

Biodiversity protection: Through the rational use of renewable resources, wild plant resources can be protected, which contributes to the protection of biodiversity and the maintenance of ecological balance.

Product quality: Compared with synthetic vanillin, natural vanillin may have more advantages in aroma quality and natural characteristics, which will help improve the quality of flavor and fragrance products.

Reduce dependence on fossil fuels: The use of renewable resources helps reduce dependence on scarce fossil fuels, which is beneficial to energy security and energy structure diversity. Hope the above information can answer your questions. If you need a reference document in English, please let me know so I can provide it to you.

IV. Conclusion

The potential of using renewable resources to produce natural vanillin as a sustainable and environmentally friendly alternative is significant. This method holds promise in addressing the increasing demand for natural vanillin while reducing the reliance on synthetic production methods.

Natural vanillin holds a crucial position in the flavor industry, valued for its characteristic aroma and widespread use as a flavoring agent in various products. It is vital to emphasize the importance of natural vanillin as a sought-after ingredient in the food, beverage, and fragrance industries due to its superior sensory profile and consumer preference for natural flavors.

Furthermore, the field of natural vanillin production presents substantial opportunities for further research and development. This includes exploring new technologies and innovative approaches to enhance the efficiency and sustainability of producing natural vanillin from renewable resources. Additionally, the development of scalable and cost-effective production methods will play a pivotal role in fostering the widespread adoption of natural vanillin as a sustainable and eco-friendly alternative in the flavor industry.

Contact Us

Grace HU (Marketing Manager) grace@biowaycn.com

Carl Cheng ( CEO/Boss ) ceo@biowaycn.com

Website: www.biowaynutrition.com

Post time: Mar-07-2024